Thungchano S Ezung

Introduction

Fruit and vegetables remain as living tissue up until the time they are consumed fresh, cooked for consumption, or processed for preservation. Controlling respiration of these living tissues would improve storability and extend shelf life of fresh produce. A certain level of respiration activity is required to prevent plant tissues from senescing and drying. Minimally processed produce such as fresh-cut fruits and vegetables are essentially wounded tissues, leading directly to tissue softening and browning discolouration on cut surfaces. The intensity of the wound response is affected by a number of factors, including species and variety, O2 and CO2 concentrations, water vapour pressure, and the presence of inhibitors. The concept of using edible coatings to extend shelf life of fresh and minimally processed produce and protect them from harmful environmental effects has been emphasized based on the need for high quality and the demand for minimal food processing and storage technologies. By regulating the transfer of moisture, oxygen, carbon dioxide, aroma and taste in a food system, edible coatings have demonstrated the capability of improving structural integrity of frozen fruits and vegetables and preventing moisture absorption and oxidation of freeze-dried fruits or vegetables. In addition, edible coatings can carry functional ingredients such as antioxidants, antimicrobials, nutrients, and flavours to further enhance food stability, quality, functionality and safety.

Use of edible coatings for fresh and minimally processed fruits and vegetables

Edible coatings have long been used to retain quality and extend shelf life of some fresh fruits and vegetables, such as citric fruits, apples, cucumbers etc. Fruits or vegetables are usually coated by dipping in or spraying with a range of edible materials so that a semi permeable membrane is formed on the surface for supressing respiration, controlling moisture loss, and providing other functions. A variety of edible materials, including lipids, polysaccharides and proteins, alone or in combinations, have been formulated to produce edible coatings. Lipid based coatings made of acetylated monoglycerides (AM),waxes(beeswax, carnauba, candelilla, paraffin and rice bran and surfactants were the first successful ones on whole fruits and vegetables and others used for reducing surface abrasion during handling and serving as moisture barrier. Colloidal suspensions of oils or waxes dispersed in water were typically early fruit coating formulations. Appropriately formulated edible coatings can be utilized for most foods to meet challenges associated with stable quality, market safety, nutritional value, and economic production cost. With regard to the fresh produce industry, the potential benefits of using edible coatings include:

1. To provide moisture barrier on the surface of produce for helping alleviate the problem of moisture loss. Moisture loss during postharvest storage of fresh produce leads to weight loss and changes in texture, flavour, appearance.

2. To provide sufficient gas barrier for controlling gas exchange between the fresh produce and its surrounding atmosphere, which would slow down respiration and delay deterioration. The gas barrier function could in turn retard the enzymatic oxidation and protect the fresh produce from browning discolouration and texture softening during storage.

3. To restrict the exchange of volatile compounds between the fresh produce and its surrounding environment through providing gas barriers, which prevents the loss of natural volatile flavour compounds and colour components from fresh produce and the acquisition of foreign odors.

4. To protect from physical damage or produced caused by mechanical impact, pressure, vibrations and other mechanical factors.

5. To act as carriers of other functional ingredients, such as antimicrobial and antioxidants agents, nutraceuticals, colour and flavour ingredients for reducing microbial loads, delaying oxidation and discolouration, and improving quality.

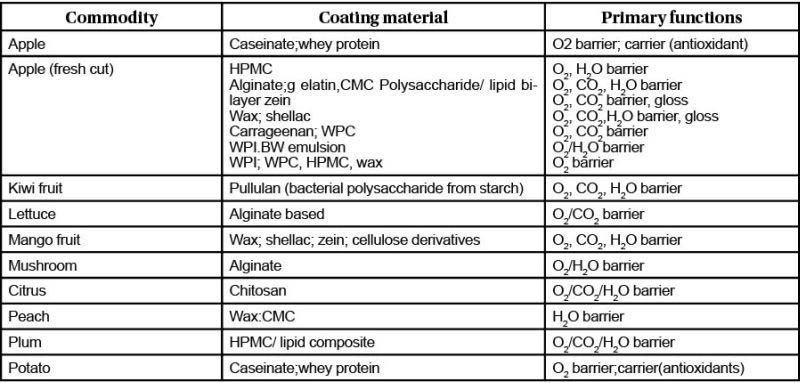

Some edible coating application on fruits and vegetables that have been investigated

Conclusion

Edible coatings can protect perishable fresh produce from deterioration by retarding dehydration, supressing respiration, improving texture quality, helping retain volatile flavour compounds and reducing microbial contamination. Along with increased market demand for fresh and minimally processed fruits and vegetables, edible coatings with unique functionality will certainly become more important in the future. Many of the polysaccharide-based coatings, especially those of inherent antimicrobial or antifungal activities, are getting more interest as substitutes for traditional lipid coatings. These coatings generally are good oxygen barriers at low to intermediate relative humidity, but relatively poor moisture barriers. Inorder to satisfy the primary goal of reducing moisture loss of fruits and vegetables with edible coatings, continous efforts are necessary to develop stable emulsions coatings with desired moisture-barrier properties. Meanwhile, studies for improving coating adhesion and durability on the surface of fruits and vegetables and investigations on sensory quality and consumer acceptance of coated products are needed.

The writer is Programme Assistant (Food Technology) KVK Wokha